Discover the new way of cleaning: Ice Blast Cleaning

It’s quicker, which means cheaper – because we don’t waste your precious time for cooling down machines, disassembling, reassembling and so on!

We don’t take you off from business for long- we let you make money!

And we you don’t need to pay for waste disposal, because there is no waste…

How does this sound to you?

For people, for equipment, for products, for environment, for very sensitive and prone to corrosion surfaces, electrics and environment.

Dry ice cleaning is non toxic, non harmful, non hazardous and non electrically conductive process as we don’t use any chemicals. Dry ice simple disappears back into the atmosphere. on contact with a surface. Sounds like magic? It’s pure science!

How do you feel about that?

We care about you and your needs. We want to deliver you the highest standards with fully understanding what is the most important for you.

We care about our planet – it is the most eco friendly method of cleaning and we are proud that we creating new trend of ecological cleaning.

Be the game changer!

We are all what you were dreaming about cleaning. We provide you superior service which is delicate and efficient in the same time.

You will be surprised how much would you like to see your every time super clean equipment which last long because it well kept and not damaged by invasive cleaning.

You will love us from fist cleaning…

We love this moment when our clients can't believe that it is the same building. Do you want to see those outstanding results?

Of course!

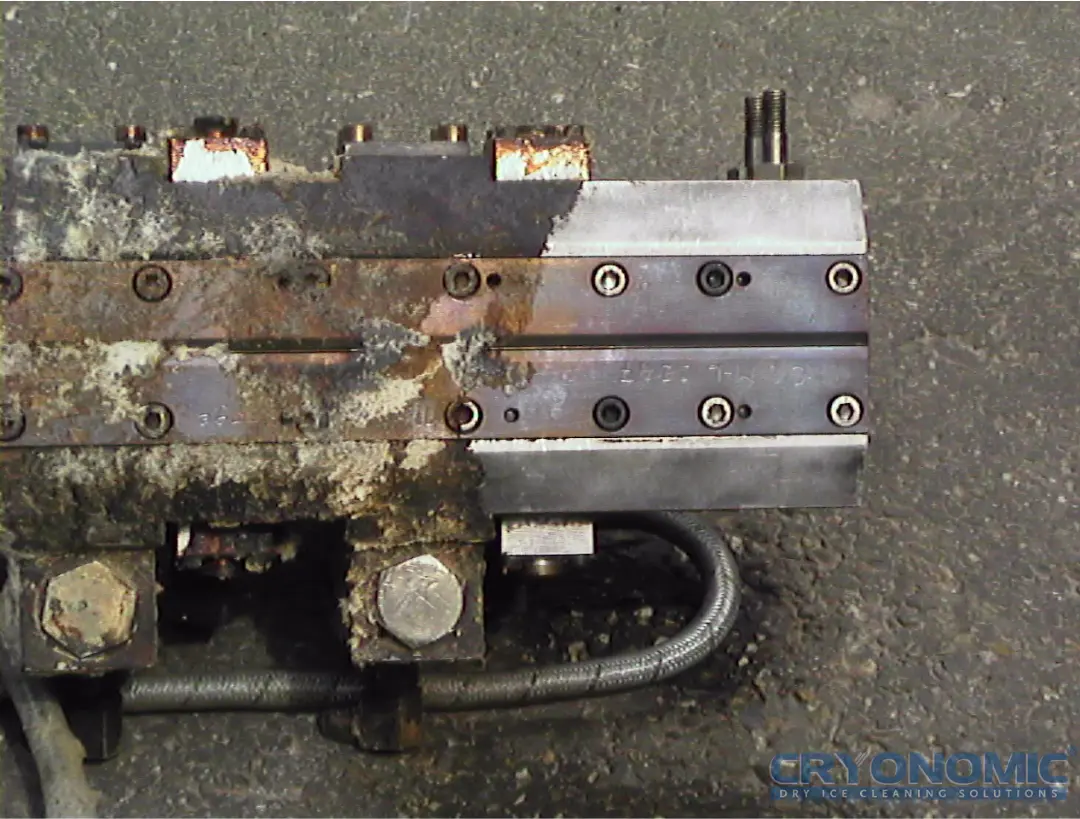

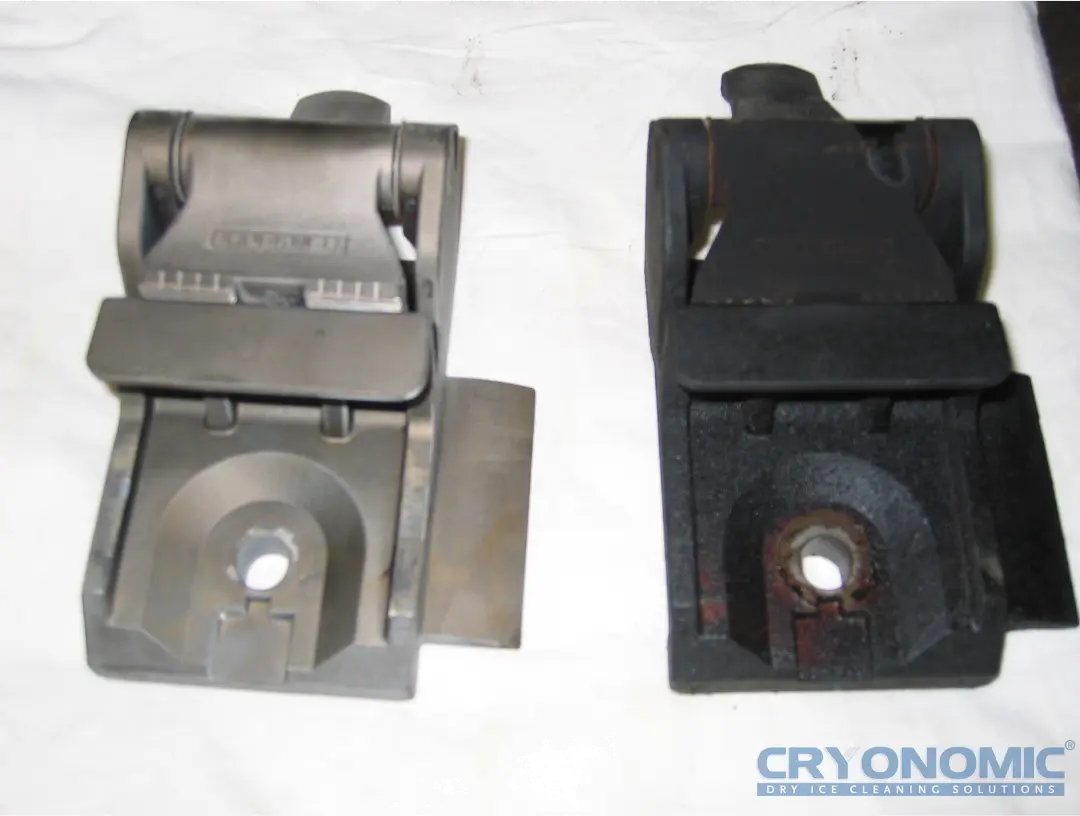

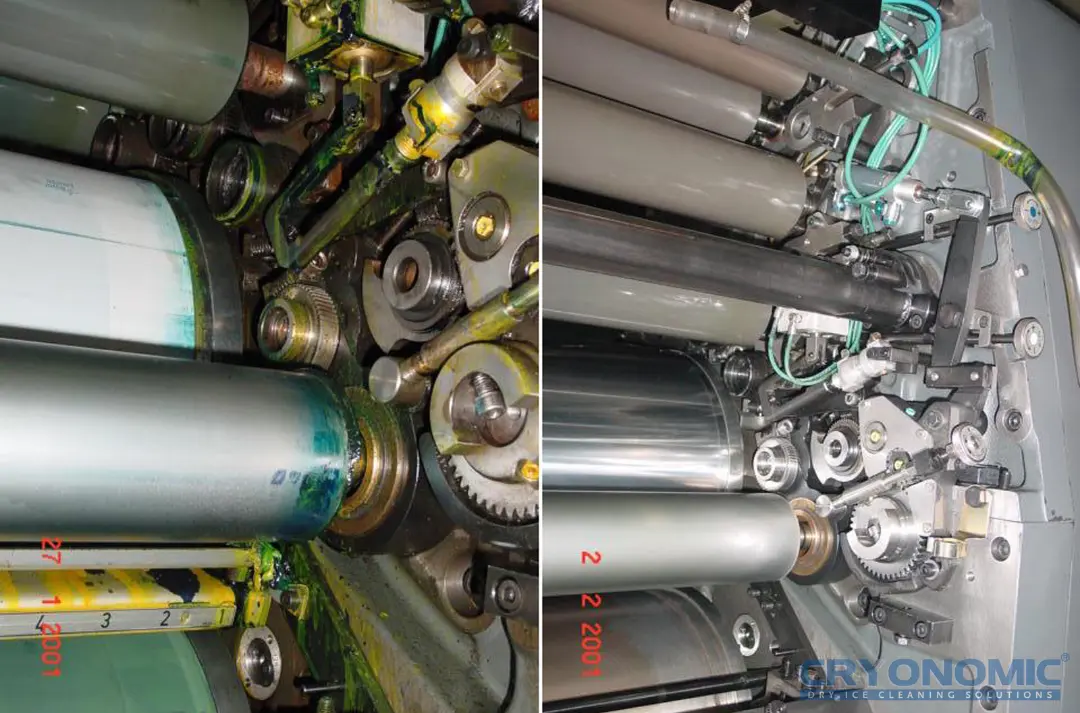

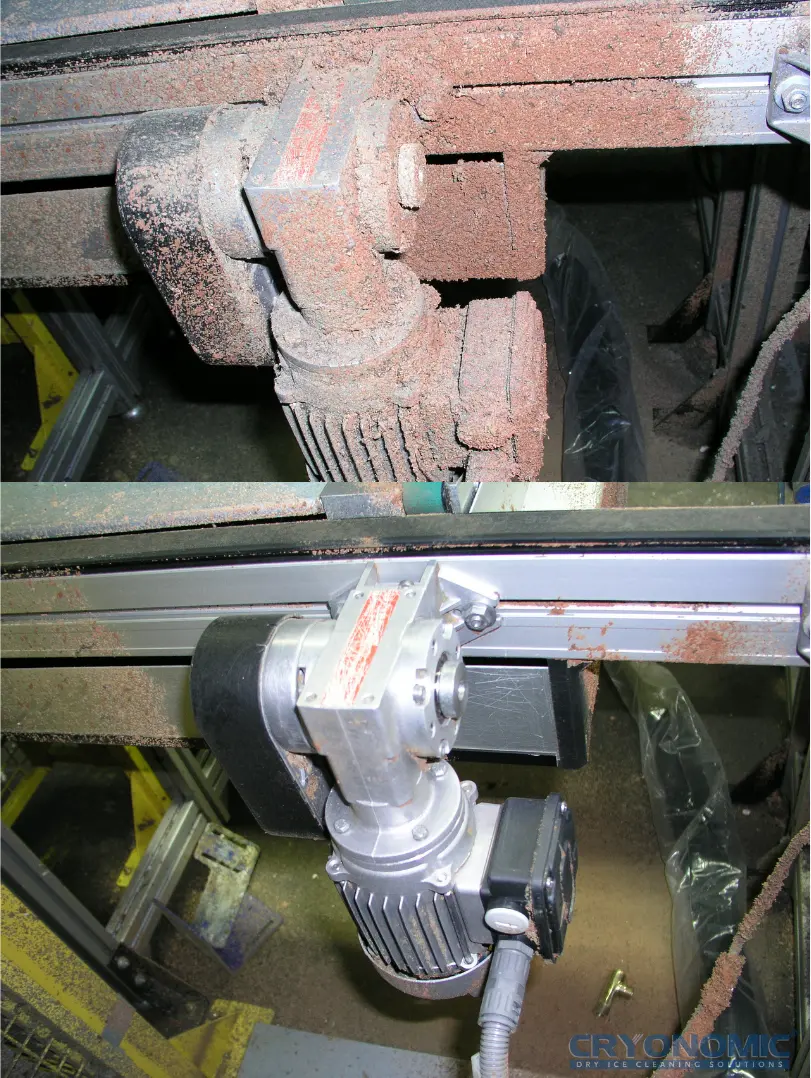

We are here to transform your factory into shiny and as good as new! Do you want to see what we can do?

Of course!

We want to make all parts of your ship are squeaky clean because we want to make sure that you are safe on your next trip. Do you want to check it out?

Of course!

Classic cars are our true passion - we understand how to bring the WOW factor without any single scratch. Do you want to learn more?

Of course!

Our ice blaster equipment uses compressed air to accelerate 3 mm pellets of dry ice to speeds over 150 m / s!

The kinetic energy combined with the very low temperature of the pellets (- 79 ° C) causes the loss of elasticity and cracking of the contamination coating. Following particles penetrate the created cracks and change there from solid to gas.

This process loosens the dirt, but does not destroy (even very delicate) surfaces. It also allows cleaning of materials prone to corrosion, contact with water and electrics.

We are a company that loves perfection – you will feel it right away: During a thorough audit, when you see us, as we prepare for work and how we come to it and finally when you see results.

We love to share these moments with our clients, when nothing is the same … Do you want to experience new standards with us?

Book free 10-minutes cleaning with us and come back for more!